Lithium-Zinc (LiZn)

What is Lithium-Zinc?

Æsir Technologies (formerly known as ZAF Energy Systems) received a Phase I NSF SBIR to research and develop a Rechargeable Aqueous Hybrid Battery (ReHAB) at the end of 2019. Since the start of the program, we have made tremendous progress in scaling the chemistry to a pouch cell and developing the major components of the battery.

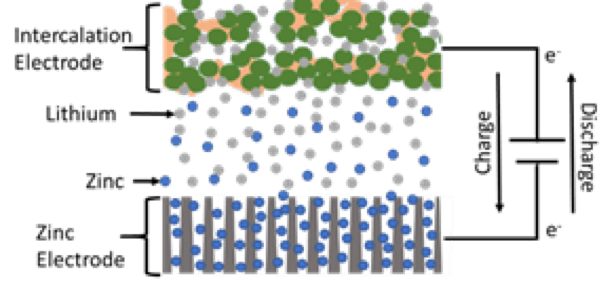

The Lithium-Zinc battery is comprised of an intercalation electrode, a zinc electrode, and an aqueous electrolyte containing ions that undergo redox intercalation/deintercalation at the intercalation electrode and deposition/dissolution at the zinc electrode. These hybrid batteries combine electrodes with high specific capacities, such as those used in lithium-ion batteries, and metal electrodes with the safe, environmentally sustainable properties such as zinc.

SUPERIOR PERFORMANCE...

UNSURPASSED SAFETY and SUSTAINABILITY

What makes Lithium-Zinc different?

The Lithium-Zinc battery will provide at least 3x the cycle life, 2x the energy density, and 2x the specific energy of lead-acid with a non-toxic, non-flammable chemistry. LiZn will outperform lead-acid without the fire and safety concerns of lithium-ion and is expected to be particularly attractive to customers needing to exceed lead-acid performance without the safety risks associated with lithium-ion. Unlike lithium-ion batteries, ReHAB does not have thermal runaway issues and can operate over a wider temperature range, due to the aqueous electrolyte.

Furthermore, the zinc-based Lithium-Zinc being developed by Æsir is fabricated with globally abundant materials, complies with region specific restrictions on hazardous substances, and can be recycled. The ReHAB chemistry is also cobalt free. Based upon early testing results, engineering projections for a 48V 8D Lithium Zinc battery, competes very favorably to 48V lithium iron phosphate (LFP). While outperforming LFP in most categories, the LiZn battery is also designed to be recyclable, safer, and less expensive.